| SKU: | |

|---|---|

| Availability: | |

| Quantity: | |

CGK015V3L; CGK025V3L CGK-025V3L; CGK030V3L CGK-030V3L; CGK040V3L CGK-040V3L

SPRSUN

A. Higher Energy Efficiency (Lower Operating Costs)

R32 has around 10% higher latent heat of vaporization than R410A, improving heat transfer efficiency.

B. Lower Global Warming Potential (GWP)

R32 has a GWP of just 675. It is close to the EU F-Gas Regulation’s post-2030 limit of GWP < 750, supporting long-term sustainability. R32 has an ODP of 0, making it an environmentally responsible choice.

C. System Compatibility & Cost Efficiency

Direct replacement for R410A, reducing retrofit costs. Requires 30% less refrigerant than R410A for equivalent cooling capacity.

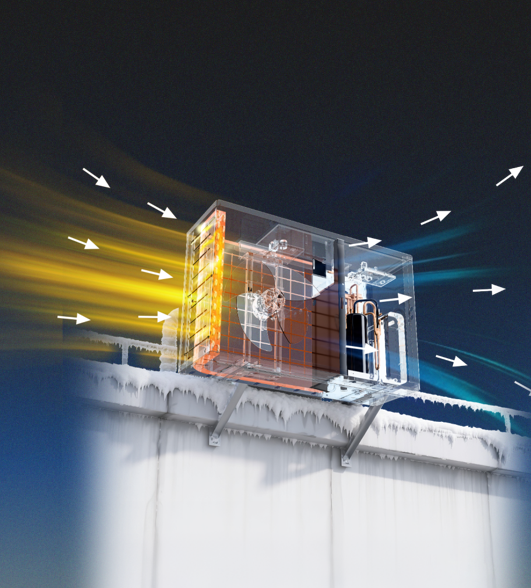

Full DC Inverter Technology

The latest full DC inverter technology integrates CAREL system's adaptive control for precise energy management.

By dynamically adjusting pressure and defrost cycles, it significantly boosts efficiency while minimizing power consumption across all operating conditions. Its advanced rotary compressor and optimized system design ensure superior stability and reduced noise levels.

Advanced Noise Reduction

The sound levels of the R32 DC inverter heat pump start as low as 42 dBA, making it the quietest system in our DC inverter lineup.

A. Silent Compartment Technology

This technology features a specialized chamber constructed from composite materials, including metal sheets and high-density sound-absorbing foam, designed to effectively "trap" the noise produced by the compressor. It significantly lowers noise levels, enhancing user comfort.

B. Multi-layer Noise Reduction Technology

Blade Design for Airflow Noise Reduction

Variable Frequency Noise Reduction Design

Sound-Absorbing Foam for Sheet Metal

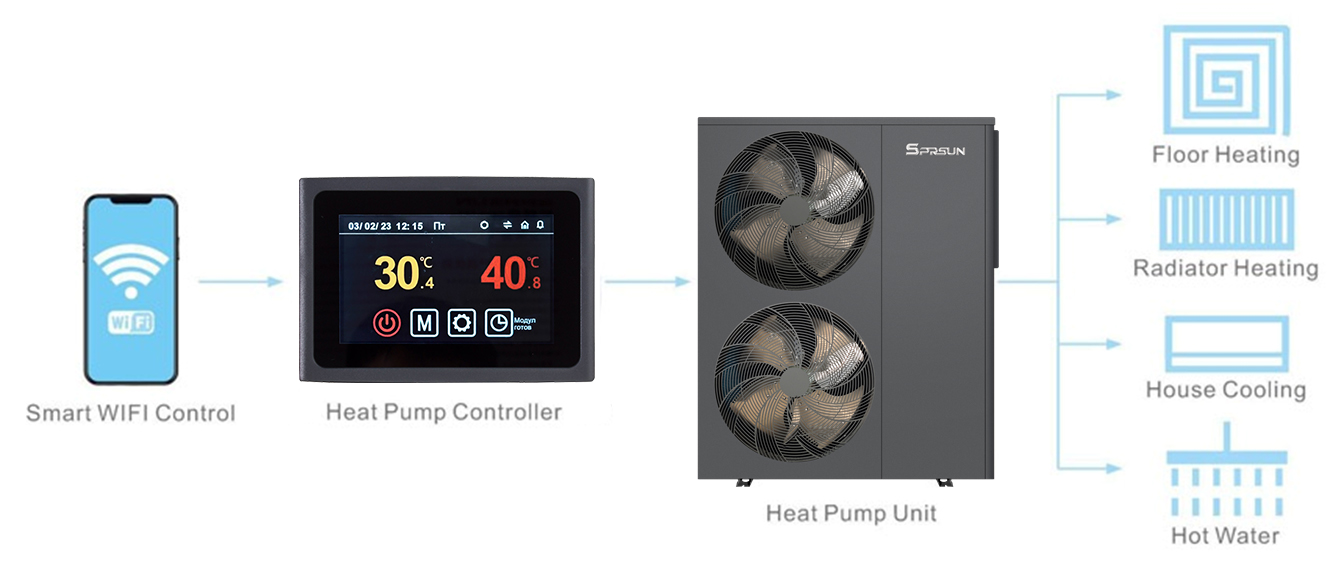

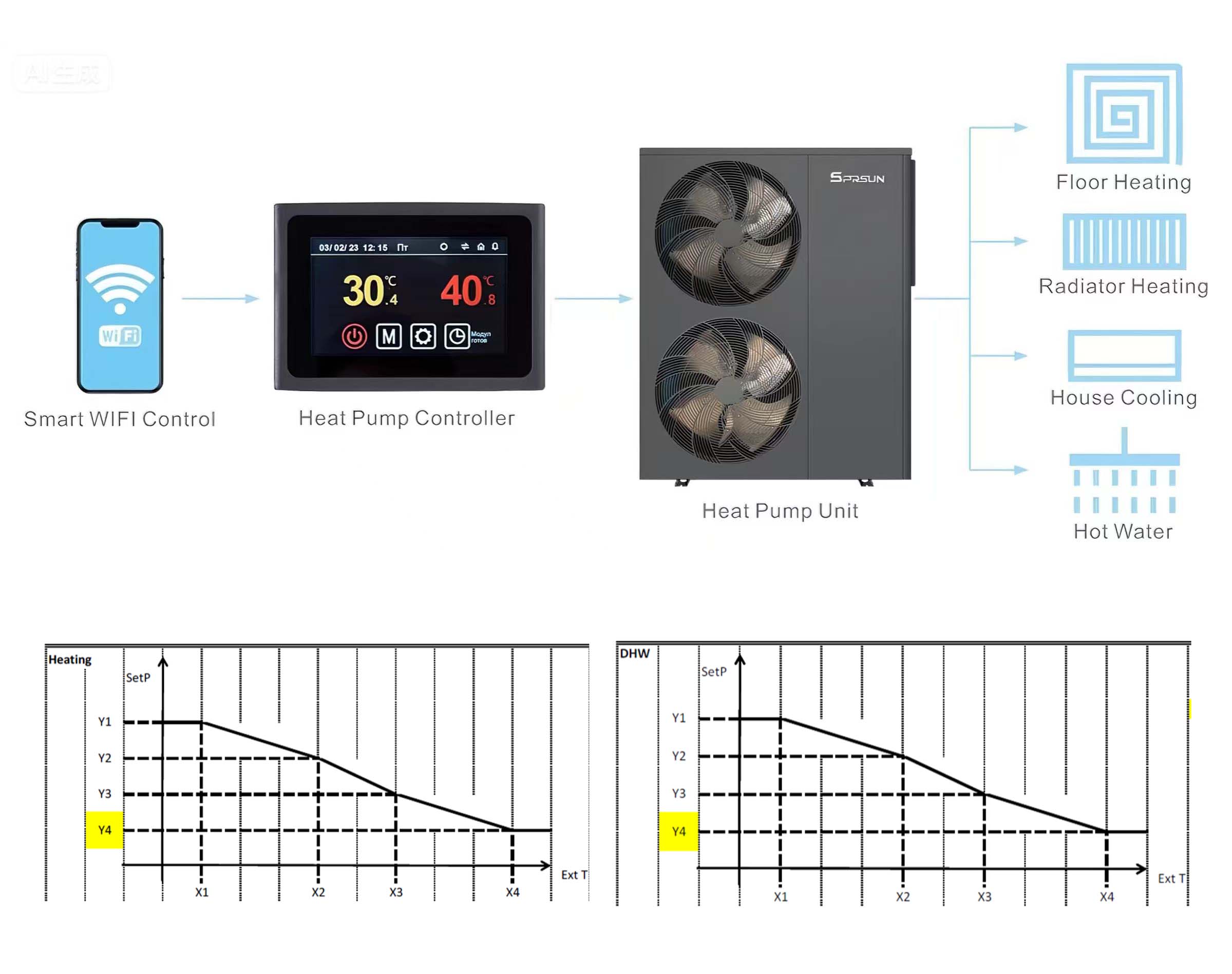

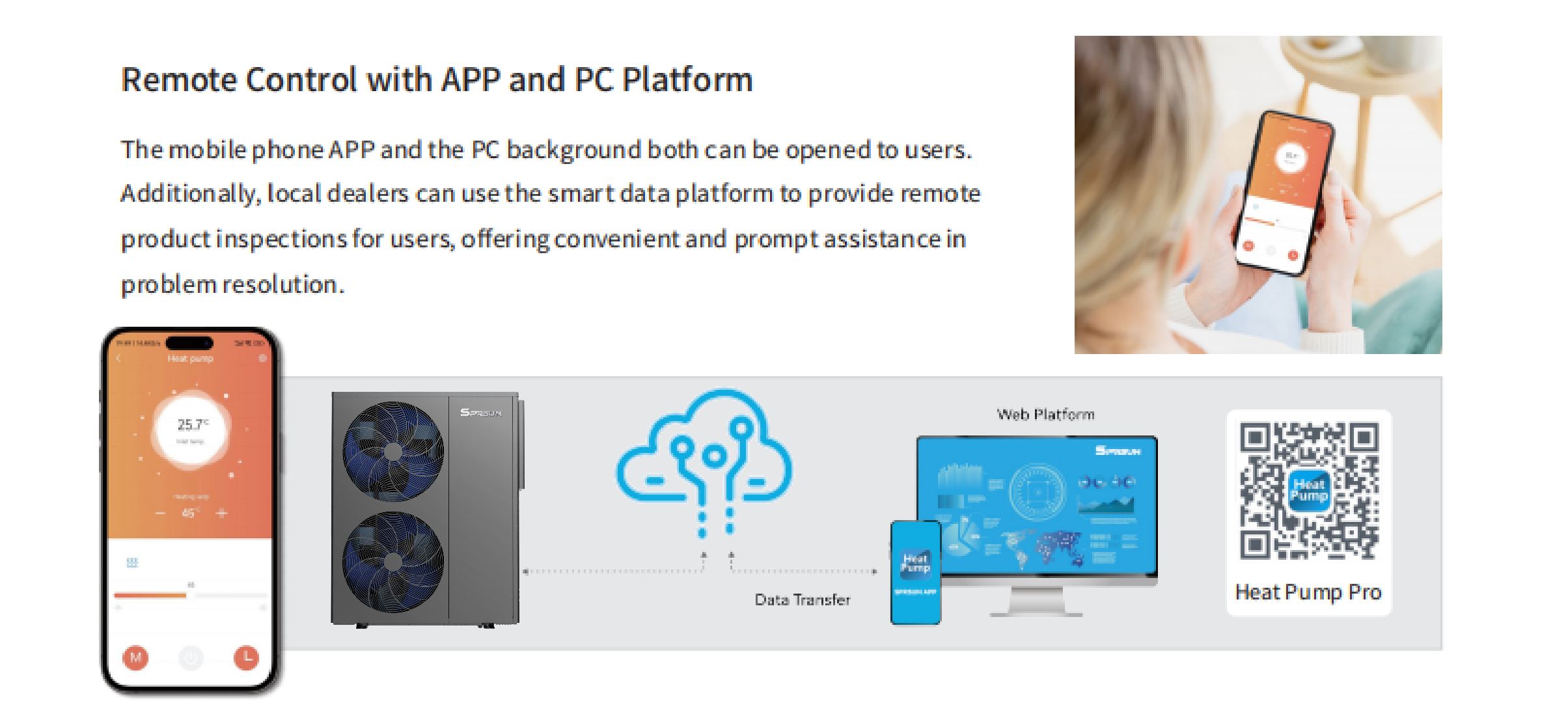

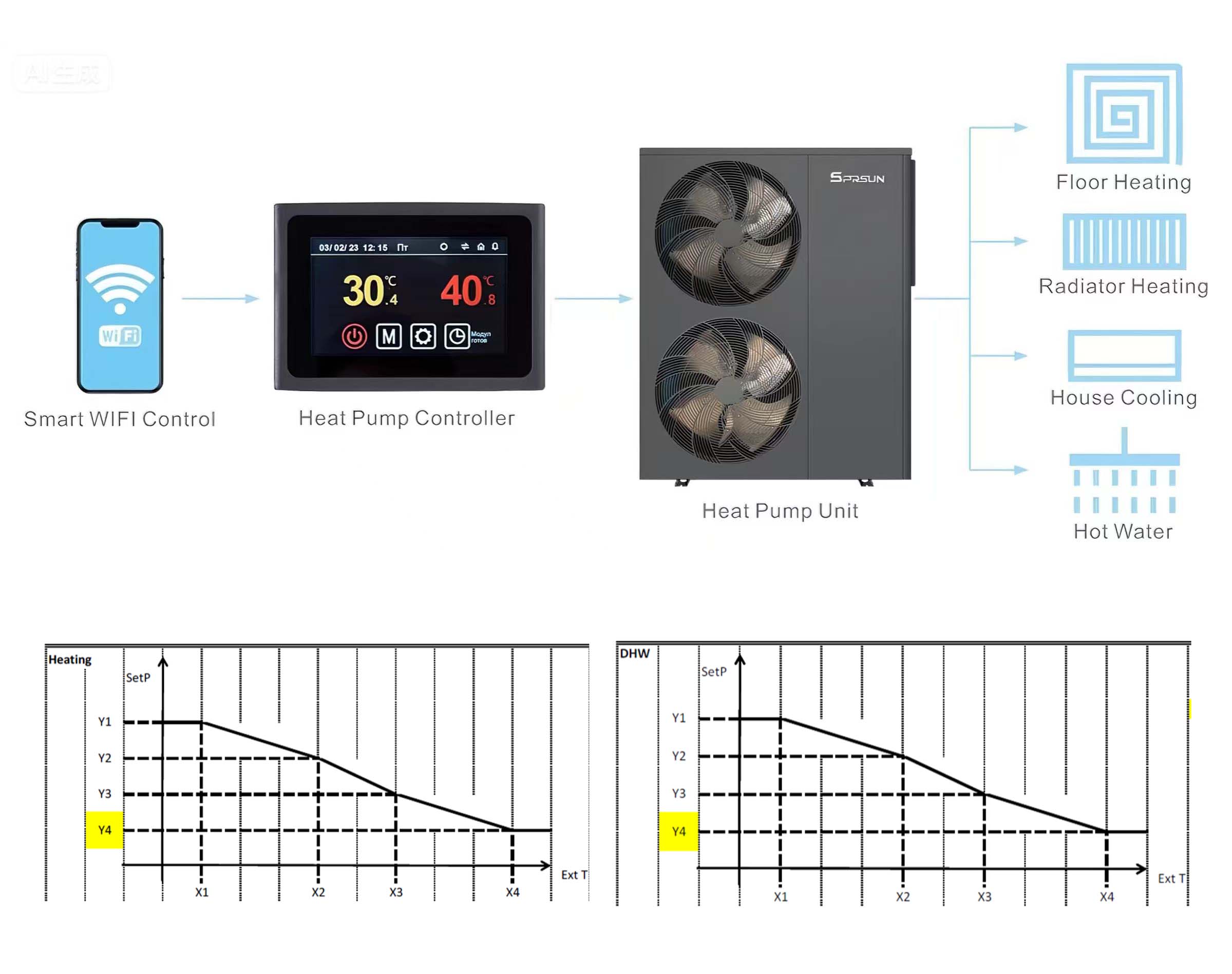

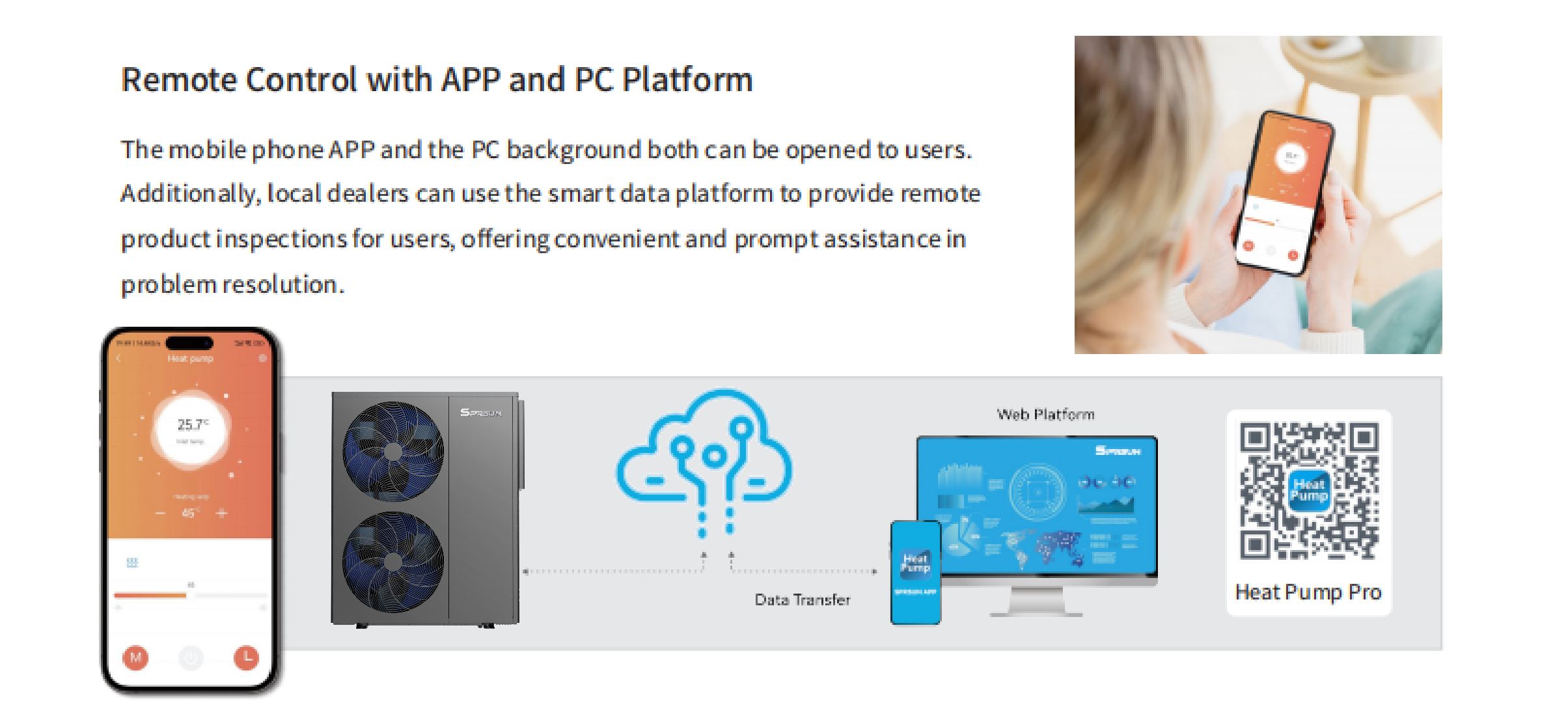

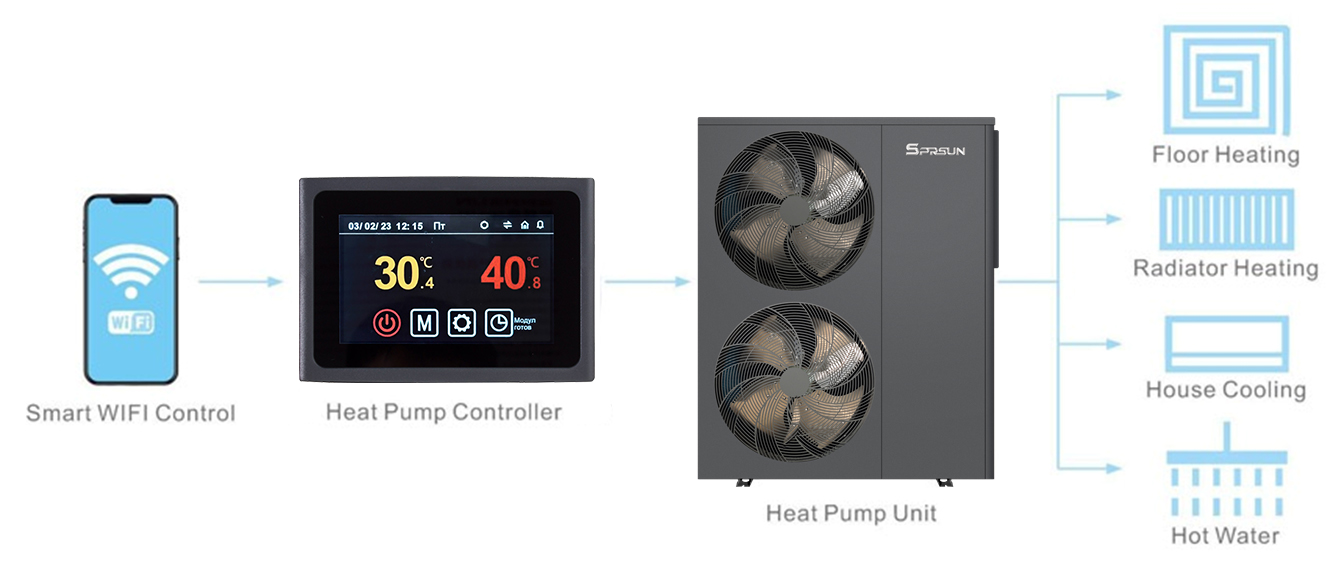

Intelligent Control System

The smart system adopts the intelligent control system, characterized by a low failure rate and stable operation. It also enables remote real-time monitoring of system operation status, one-click updates, and intelligent defrosting.

Real-time Monitor

The intelligent control system can monitor the working condition of the heat pump in real time and send out timely alarms when abnormalities are found.

High Immunity

Effective Handling Of Voltage Fluctuations And Rapid Climate Shifts

Enhanced Efficiency

The Smart System Leverages the Compressor Operating Envelope to Achieve Peak Efficiency

Short Defrost Cycle:

H04: Ambient temperature for defrosting - 15°C

H07: Defrosting environment and evaporator coil temperature difference 1 - 7°C

H08: Defrosting period 1 - 45min

Medium Defrost Cycle:

H09: Ambient temperature for defrosting - minus 2°C

H10: Defrosting environment and evaporator coil temperature difference 2 - 6°C

H11: Defrosting period 2 - 60min

Extended Defrost Cycle:

H12: Ambient temperature for defrosting - minus 10°C

H13: Defrosting environment and evaporator coil temperature difference 3 - 5°C

H14: Defrosting period 3 - 90min

The front grille features a seamless sheet metal design for a sleek and minimalist look.

The air outlet frame and the entire unit are finished in contrasting gray and matte black colors, enhancing the overall aesthetic appeal.

The use of aluminum alloy serrated fan blades significantly reduces wind noise.

The compressor features dual shock absorption, effectively minimizing noise and resonance caused by the high-frequency operation of the compressor.

Water inlet and outlet pipes discharge water from the right rear.

Key Advantages:

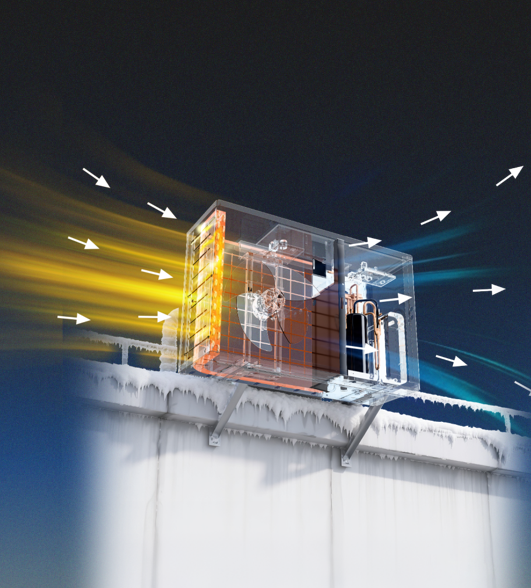

High Efficiency in Extreme Cold

Maintains superior heating performance even at -25°C, with a COP markedly higher than conventional heat pumps, reducing reliance on auxiliary electric heating.

Inverter Synergy

Dynamically adjusts vapor injection volume in coordination with variable-frequency speed control to achieve precise load matching.

Enhanced Reliability

Lowers compressor discharge temperature, extending equipment service life.

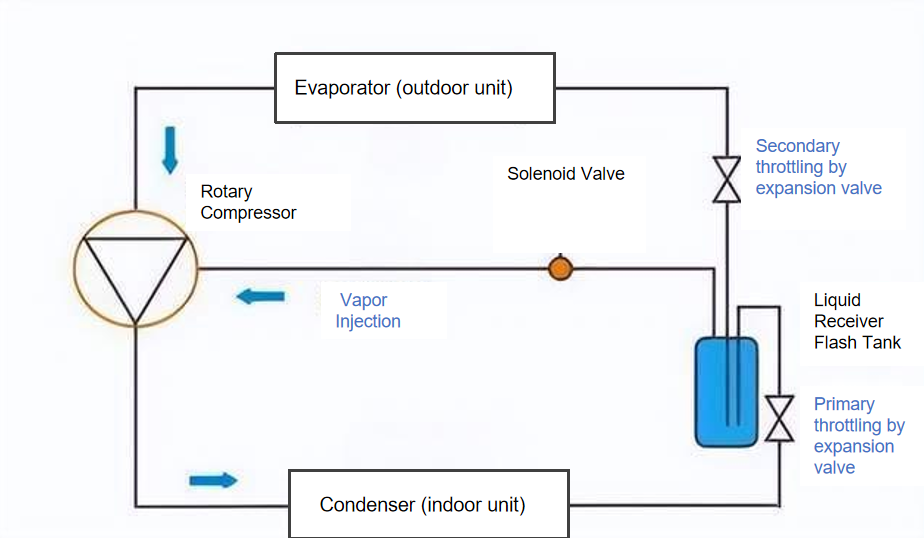

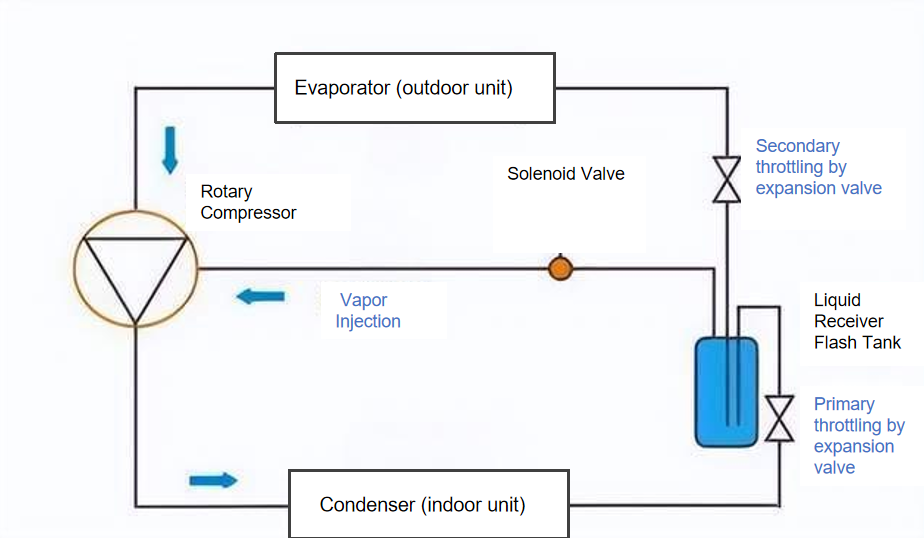

EVI(Enhanced Vapor Injection) is an advanced vapor-compression refrigeration cycle that boosts heat pump efficiency in low ambient conditions.

Two-Stage Compression with Flash Tank:

Subcooled liquid refrigerant flashes into intermediate pressure vapor in a flash tank, injected into the compressor’s mid-stage port.

Effectively lowers discharge temperature while increasing refrigerant mass flow.

Optimized Subcooling & Capacity

The flash tank ensures liquid refrigerant is maximally subcooled before the evaporator, improving evaporation efficiency.

Mid-compression injection raises system capacity without excessive compressor load.

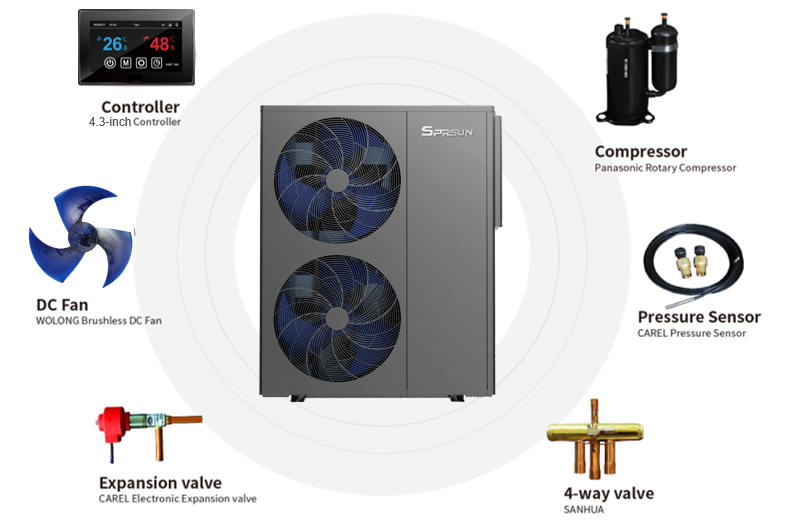

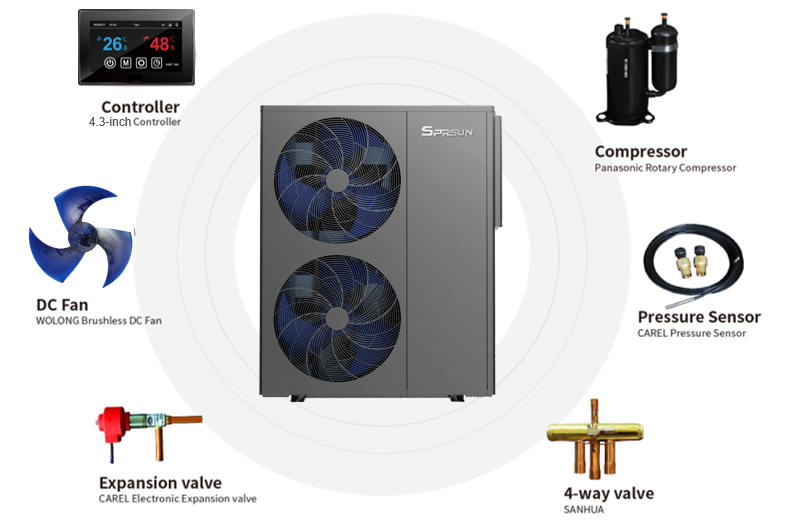

Panasonic Rotary Compressor

Approximately 10% more efficient than traditional R410A models.

Lower operating noise through rotor dynamic balance optimisation.

The unit can operate in a wide range of temperatures: -25°C to 45°C.

CAREL Electric Expansion Valve

Ensures high-precision control, low failure rate, and longer service life.

Bidirectional refrigerant flow.

High precision control and wide size range.

Hermetically welded versions with stainless steel body and copper connections to minimize refrigerant losses.

Refrigerant temperature up to 100°C.

Solutions with integrated drivers.

CAREL INVERTER POWER

Designed specifically to drive BLDC compressors.

Dedicated protection functions.

1ph and 3ph with active or passive EMc filters.

High quality certifications (CE, UL, Safety, EMC..).

Integrated Modbus connectivity

CAREL PRESSURE TRANSDUCERS (SPKT / SPKS)

Precise measurement and high EMC immunity

CAREL - TEMPERATURE SENSORS

With the most advanced technology in the compressor and system The heat pump is able to supply hot water to 75 degrees Celsius, which makes it suitable for:

Fast reading sensors for fast response for superheat control.

High temperature sensors to read the compressor discharge temperature.

A. Higher Energy Efficiency (Lower Operating Costs)

R32 has around 10% higher latent heat of vaporization than R410A, improving heat transfer efficiency.

B. Lower Global Warming Potential (GWP)

R32 has a GWP of just 675. It is close to the EU F-Gas Regulation’s post-2030 limit of GWP < 750, supporting long-term sustainability. R32 has an ODP of 0, making it an environmentally responsible choice.

C. System Compatibility & Cost Efficiency

Direct replacement for R410A, reducing retrofit costs. Requires 30% less refrigerant than R410A for equivalent cooling capacity.

Full DC Inverter Technology

The latest full DC inverter technology integrates CAREL system's adaptive control for precise energy management.

By dynamically adjusting pressure and defrost cycles, it significantly boosts efficiency while minimizing power consumption across all operating conditions. Its advanced rotary compressor and optimized system design ensure superior stability and reduced noise levels.

Advanced Noise Reduction

The sound levels of the R32 DC inverter heat pump start as low as 42 dBA, making it the quietest system in our DC inverter lineup.

A. Silent Compartment Technology

This technology features a specialized chamber constructed from composite materials, including metal sheets and high-density sound-absorbing foam, designed to effectively "trap" the noise produced by the compressor. It significantly lowers noise levels, enhancing user comfort.

B. Multi-layer Noise Reduction Technology

Blade Design for Airflow Noise Reduction

Variable Frequency Noise Reduction Design

Sound-Absorbing Foam for Sheet Metal

Intelligent Control System

The smart system adopts the intelligent control system, characterized by a low failure rate and stable operation. It also enables remote real-time monitoring of system operation status, one-click updates, and intelligent defrosting.

Real-time Monitor

The intelligent control system can monitor the working condition of the heat pump in real time and send out timely alarms when abnormalities are found.

High Immunity

Effective Handling Of Voltage Fluctuations And Rapid Climate Shifts

Enhanced Efficiency

The Smart System Leverages the Compressor Operating Envelope to Achieve Peak Efficiency

Short Defrost Cycle:

H04: Ambient temperature for defrosting - 15°C

H07: Defrosting environment and evaporator coil temperature difference 1 - 7°C

H08: Defrosting period 1 - 45min

Medium Defrost Cycle:

H09: Ambient temperature for defrosting - minus 2°C

H10: Defrosting environment and evaporator coil temperature difference 2 - 6°C

H11: Defrosting period 2 - 60min

Extended Defrost Cycle:

H12: Ambient temperature for defrosting - minus 10°C

H13: Defrosting environment and evaporator coil temperature difference 3 - 5°C

H14: Defrosting period 3 - 90min

The front grille features a seamless sheet metal design for a sleek and minimalist look.

The air outlet frame and the entire unit are finished in contrasting gray and matte black colors, enhancing the overall aesthetic appeal.

The use of aluminum alloy serrated fan blades significantly reduces wind noise.

The compressor features dual shock absorption, effectively minimizing noise and resonance caused by the high-frequency operation of the compressor.

Water inlet and outlet pipes discharge water from the right rear.

Key Advantages:

High Efficiency in Extreme Cold

Maintains superior heating performance even at -25°C, with a COP markedly higher than conventional heat pumps, reducing reliance on auxiliary electric heating.

Inverter Synergy

Dynamically adjusts vapor injection volume in coordination with variable-frequency speed control to achieve precise load matching.

Enhanced Reliability

Lowers compressor discharge temperature, extending equipment service life.

EVI(Enhanced Vapor Injection) is an advanced vapor-compression refrigeration cycle that boosts heat pump efficiency in low ambient conditions.

Two-Stage Compression with Flash Tank:

Subcooled liquid refrigerant flashes into intermediate pressure vapor in a flash tank, injected into the compressor’s mid-stage port.

Effectively lowers discharge temperature while increasing refrigerant mass flow.

Optimized Subcooling & Capacity

The flash tank ensures liquid refrigerant is maximally subcooled before the evaporator, improving evaporation efficiency.

Mid-compression injection raises system capacity without excessive compressor load.

Panasonic Rotary Compressor

Approximately 10% more efficient than traditional R410A models.

Lower operating noise through rotor dynamic balance optimisation.

The unit can operate in a wide range of temperatures: -25°C to 45°C.

CAREL Electric Expansion Valve

Ensures high-precision control, low failure rate, and longer service life.

Bidirectional refrigerant flow.

High precision control and wide size range.

Hermetically welded versions with stainless steel body and copper connections to minimize refrigerant losses.

Refrigerant temperature up to 100°C.

Solutions with integrated drivers.

CAREL INVERTER POWER

Designed specifically to drive BLDC compressors.

Dedicated protection functions.

1ph and 3ph with active or passive EMc filters.

High quality certifications (CE, UL, Safety, EMC..).

Integrated Modbus connectivity

CAREL PRESSURE TRANSDUCERS (SPKT / SPKS)

Precise measurement and high EMC immunity

CAREL - TEMPERATURE SENSORS

With the most advanced technology in the compressor and system The heat pump is able to supply hot water to 75 degrees Celsius, which makes it suitable for:

Fast reading sensors for fast response for superheat control.

High temperature sensors to read the compressor discharge temperature.

1. R32 Refrigerant

Widely adopted eco-efficient solution

2. 3-in-1 Functionality

One unit for heating, cooling, and domestic hot water all year round.

3. High Outlet Water Temperature

Delivers up to 60°C for comfortable heating and various applications.

4. High Energy Efficiency

ErP A+++ at 35°C / A++ at 55°C, ensuring lower energy consumption.

5. Wide Operating Conditions

Stable performance from –25°C to 45°C ambient temperatures.

6. Smart Control

Standard APP remote control and IoT cloud platform for easy monitoring.

7. EVI System

Efficient heating at ultra-low temp (Max. COP 5.95)

| Model | CGK015V3L | CGK025V3L | CGK030V3L | CGK040V3L | CGK-025V3L | CGK-030V3L | CGK-040V3L | ||||||||||||||||

| Power Supply / Refrigerant | V/Hz/Ph | 220-240/50/1 - R32 | 380-420/50/3 - R32 | ||||||||||||||||||||

| Max. Heating Capacity (1) | kW | 6 | 9.5 | 12 | 16 | 9.5 | 12 | 16 | |||||||||||||||

| C.O.P (1) | W/W | 4.45 | 4.58 | 4.45 | 4.71 | 4.58 | 4.45 | 4.71 | |||||||||||||||

| Heating Capacity Min./Max.(1) | kW | 2.76 | / | 6 | 4.37 | / | 9.5 | 5.52 | / | 12 | 7.36 | / | 16 | 4.37 | / | 9.5 | 5.52 | / | 12 | 7.36 | / | 16 | |

| Heating Power Input Min./Max.(1) | W | 496 | / | 1348 | 763 | / | 2074 | 992 | / | 2697 | 1250 | / | 3397 | 763 | / | 2074 | 992 | / | 2697 | 1250 | / | 3397 | |

| C.O.P Min./Max.(1) | W/W | 4.45 | / | 5.56 | 4.58 | / | 5.73 | 4.45 | / | 5.56 | 4.71 | / | 5.89 | 4.58 | / | 5.73 | 4.45 | / | 5.56 | 4.71 | / | 5.89 | |

| Max. Heating Capacity(2) | kW | 5.8 | 9.1 | 11.5 | 15.4 | 9.1 | 11.5 | 15.4 | |||||||||||||||

| C.O.P (2) | W/W | 3.60 | 3.71 | 3.60 | 3.82 | 3.71 | 3.60 | 3.82 | |||||||||||||||

| Heating Capacity Min./Max.(2) | kW | 2.65 | / | 5.76 | 4.20 | / | 9.12 | 5.30 | / | 11.52 | 7.07 | / | 15.36 | 4.20 | / | 9.12 | 5.30 | / | 11.52 | 7.07 | / | 15.36 | |

| Heating power input Min./Max.(2) | W | 627 | / | 1618 | 964 | / | 2489 | 1254 | / | 3236 | 1579 | / | 4076 | 964 | / | 2489 | 1254 | / | 3236 | 1579 | / | 4076 | |

| C.O.P Min./Max.(2) | W/W | 3.56 | / | 4.23 | 3.66 | / | 4.35 | 3.56 | / | 4.23 | 3.77 | / | 4.47 | 3.66 | / | 4.35 | 3.56 | / | 4.23 | 3.77 | / | 4.47 | |

| Max. Cooling Capacity(3) | kW | 5.5 | 8.7 | 10.9 | 14.6 | 8.7 | 10.9 | 14.6 | |||||||||||||||

| E.E.R (3) | W/W | 3.50 | 3.60 | 3.50 | 3.70 | 3.60 | 3.50 | 3.70 | |||||||||||||||

| Cooling Capacity Min./Max.(3) | kW | 2.52 | / | 5.47 | 3.99 | / | 8.66 | 5.03 | / | 10.94 | 6.71 | / | 14.59 | 3.99 | / | 8.66 | 5.03 | / | 10.94 | 6.71 | / | 14.59 | |

| Cooling Power Input Min./Max.(3) | W | 608 | / | 1852 | 935 | / | 2849 | 1215 | / | 3704 | 1531 | / | 4666 | 935 | / | 2849 | 1215 | / | 3704 | 1531 | / | 4666 | |

| E.E.R Min./Max.(3) | W/W | 2.95 | / | 4.14 | 3.04 | / | 4.26 | 2.95 | / | 4.14 | 3.13 | / | 4.39 | 3.04 | / | 4.26 | 2.95 | / | 4.14 | 3.13 | / | 4.39 | |

| Max. Cooling Capacity(4) | kW | 4.3 | 6.2 | 8.6 | 10.4 | 6.2 | 8.6 | 10.4 | |||||||||||||||

| E.E.R(4) | W/W | 2.52 | 2.59 | 2.62 | 2.66 | 2.59 | 2.62 | 2.66 | |||||||||||||||

| Cooling Capacity Min./Max.(4) | kW | 1.99 | / | 4.32 | 2.85 | / | 6.20 | 3.97 | / | 8.64 | 4.80 | / | 10.44 | 2.85 | / | 6.20 | 3.97 | / | 8.64 | 4.80 | / | 10.44 | |

| Cooling Power Input Min./Max.(4) | W | 545 | / | 1720 | 760 | / | 2399 | 1090 | / | 3440 | 1245 | / | 3929 | 760 | / | 2399 | 1090 | / | 3440 | 1245 | / | 3929 | |

| E.E.R Min./Max.(4) | W/W | 2.51 | / | 3.65 | 2.58 | / | 3.75 | 2.51 | / | 3.65 | 2.66 | / | 3.86 | 2.58 | / | 3.75 | 2.51 | / | 3.65 | 2.66 | / | 3.86 | |

| Water Flow | m3/h | 1.04 | 1.63 | 2.06 | 2.75 | 1.63 | 2.06 | 2.75 | |||||||||||||||

| Hot Water Flow Rate | L/h | 125 | 196 | 247 | 331 | 196 | 247 | 331 | |||||||||||||||

| Rated Current | A | 6.5 | 9.9 | 12.9 | 16.3 | 4.4 | 5.7 | 7.2 | |||||||||||||||

| Max Power Input | kW | 2.0 | 3.0 | 3.9 | 4.9 | 3.0 | 3.9 | 4.9 | |||||||||||||||

| Max Current | A | 9.4 | 14.4 | 18.7 | 23.6 | 6.3 | 8.3 | 10.4 | |||||||||||||||

| Wire diameter | mm² | 2.5 | 4.0 | 4.0 | 6.0 | 2.5 | 2.5 | 2.5 | |||||||||||||||

| Fuse or Circuit breaker | A | 16A | 20A | 25A | 32A | 13A | 13A | 16A | |||||||||||||||

| Compressor | Type - Quantity/System | Twin Rotary - 1 | |||||||||||||||||||||

| Fan | Quantity | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |||||||||||||||

| Airflow | m3/h | 1500 | 2500 | 3000 | 3500 | 2500 | 3000 | 3500 | |||||||||||||||

| Rated power | W | 60 | 80 | 100 | 120 | 80 | 100 | 120 | |||||||||||||||

| Water Side Heat Exchanger | Type | Plate Heat Exchanger | |||||||||||||||||||||

| Water Pressure Drop | kPa | 14 | 18 | 20 | 21 | 18 | 20 | 21 | |||||||||||||||

| Piping Connection | Inch | G3/4" | G1" | G1" | G1" | G1" | G1" | G1" | |||||||||||||||

| Allowable Water Flow | Min./Rated./Max. | L/S | 0.18 | 0.29 | 0.48 | 0.28 | 0.45 | 0.76 | 0.36 | 0.57 | 0.96 | 0.48 | 0.76 | 1.27 | 0.28 | 0.45 | 0.76 | 0.36 | 0.57 | 0.96 | 0.48 | 0.76 | 1.27 |

| Sound pressure level(1m) | dB(A) | 40.8~50.8 | 41.6~50.1 | 41.4~51.5 | 46.9~57.1 | 38.7~49.4 | 41.2~51.4 | 42~55.4 | |||||||||||||||

| Sound power level(1m) | dB(A) | 60.1 | 61.2 | 63.2 | 64.2 | 61.4 | 63.7 | 64.2 | |||||||||||||||

| Net Dimension(L×D×H) | mm | 990*375*655 | 1110*475*810 | 1110*475*810 | 1110*475*960 | 1110*475*810 | 1110*475*810 | 1110*475*960 | |||||||||||||||

| Carton packing Dimension(L×D×H) | mm | 1165*505*960 | 1165*505*960 | 1165*505*1110 | 1165*505*960 | 1165*505*960 | 1165*505*1110 | ||||||||||||||||

| Splint packing Dimension(L×D×H) | mm | 1070*405*800 | 1210*540*960 | 1210*540*960 | 1210*540*1110 | 1210*540*960 | 1210*540*960 | 1210*540*1110 | |||||||||||||||

| Net Weight | Kg | 59 | 96 | 104 | 114 | 96 | 102 | 114 | |||||||||||||||

| Carton gross Weight | Kg | 114 | 124 | 114 | 122 | ||||||||||||||||||

| Splint gross Weight | Kg | 80 | 131 | 141 | 126 | 131 | 139 | 126 | |||||||||||||||

| Note: (1) Heating condition: water inlet/outlet temperature: 30℃/35℃, Ambient temperature: DB 7℃/WB 6℃; | |||||||||||||||||||||||

| (2) Heating condition: water inlet/outlet temperature: 40℃/45℃, Ambient temperature: DB 7℃/WB 6℃; | |||||||||||||||||||||||

| (3) Cooling condition: water inlet/outlet temperature: 23℃/18℃, Ambient temperature: DB35℃/WB24℃; | |||||||||||||||||||||||

| (4) Cooling condition: water inlet/outlet temperature: 12℃/7℃, Ambient temperature: DB35℃/WB24℃; | |||||||||||||||||||||||

1. R32 Refrigerant

Widely adopted eco-efficient solution

2. 3-in-1 Functionality

One unit for heating, cooling, and domestic hot water all year round.

3. High Outlet Water Temperature

Delivers up to 60°C for comfortable heating and various applications.

4. High Energy Efficiency

ErP A+++ at 35°C / A++ at 55°C, ensuring lower energy consumption.

5. Wide Operating Conditions

Stable performance from –25°C to 45°C ambient temperatures.

6. Smart Control

Standard APP remote control and IoT cloud platform for easy monitoring.

7. EVI System

Efficient heating at ultra-low temp (Max. COP 5.95)

| Model | CGK015V3L | CGK025V3L | CGK030V3L | CGK040V3L | CGK-025V3L | CGK-030V3L | CGK-040V3L | ||||||||||||||||

| Power Supply / Refrigerant | V/Hz/Ph | 220-240/50/1 - R32 | 380-420/50/3 - R32 | ||||||||||||||||||||

| Max. Heating Capacity (1) | kW | 6 | 9.5 | 12 | 16 | 9.5 | 12 | 16 | |||||||||||||||

| C.O.P (1) | W/W | 4.45 | 4.58 | 4.45 | 4.71 | 4.58 | 4.45 | 4.71 | |||||||||||||||

| Heating Capacity Min./Max.(1) | kW | 2.76 | / | 6 | 4.37 | / | 9.5 | 5.52 | / | 12 | 7.36 | / | 16 | 4.37 | / | 9.5 | 5.52 | / | 12 | 7.36 | / | 16 | |

| Heating Power Input Min./Max.(1) | W | 496 | / | 1348 | 763 | / | 2074 | 992 | / | 2697 | 1250 | / | 3397 | 763 | / | 2074 | 992 | / | 2697 | 1250 | / | 3397 | |

| C.O.P Min./Max.(1) | W/W | 4.45 | / | 5.56 | 4.58 | / | 5.73 | 4.45 | / | 5.56 | 4.71 | / | 5.89 | 4.58 | / | 5.73 | 4.45 | / | 5.56 | 4.71 | / | 5.89 | |

| Max. Heating Capacity(2) | kW | 5.8 | 9.1 | 11.5 | 15.4 | 9.1 | 11.5 | 15.4 | |||||||||||||||

| C.O.P (2) | W/W | 3.60 | 3.71 | 3.60 | 3.82 | 3.71 | 3.60 | 3.82 | |||||||||||||||

| Heating Capacity Min./Max.(2) | kW | 2.65 | / | 5.76 | 4.20 | / | 9.12 | 5.30 | / | 11.52 | 7.07 | / | 15.36 | 4.20 | / | 9.12 | 5.30 | / | 11.52 | 7.07 | / | 15.36 | |

| Heating power input Min./Max.(2) | W | 627 | / | 1618 | 964 | / | 2489 | 1254 | / | 3236 | 1579 | / | 4076 | 964 | / | 2489 | 1254 | / | 3236 | 1579 | / | 4076 | |

| C.O.P Min./Max.(2) | W/W | 3.56 | / | 4.23 | 3.66 | / | 4.35 | 3.56 | / | 4.23 | 3.77 | / | 4.47 | 3.66 | / | 4.35 | 3.56 | / | 4.23 | 3.77 | / | 4.47 | |

| Max. Cooling Capacity(3) | kW | 5.5 | 8.7 | 10.9 | 14.6 | 8.7 | 10.9 | 14.6 | |||||||||||||||

| E.E.R (3) | W/W | 3.50 | 3.60 | 3.50 | 3.70 | 3.60 | 3.50 | 3.70 | |||||||||||||||

| Cooling Capacity Min./Max.(3) | kW | 2.52 | / | 5.47 | 3.99 | / | 8.66 | 5.03 | / | 10.94 | 6.71 | / | 14.59 | 3.99 | / | 8.66 | 5.03 | / | 10.94 | 6.71 | / | 14.59 | |

| Cooling Power Input Min./Max.(3) | W | 608 | / | 1852 | 935 | / | 2849 | 1215 | / | 3704 | 1531 | / | 4666 | 935 | / | 2849 | 1215 | / | 3704 | 1531 | / | 4666 | |

| E.E.R Min./Max.(3) | W/W | 2.95 | / | 4.14 | 3.04 | / | 4.26 | 2.95 | / | 4.14 | 3.13 | / | 4.39 | 3.04 | / | 4.26 | 2.95 | / | 4.14 | 3.13 | / | 4.39 | |

| Max. Cooling Capacity(4) | kW | 4.3 | 6.2 | 8.6 | 10.4 | 6.2 | 8.6 | 10.4 | |||||||||||||||

| E.E.R(4) | W/W | 2.52 | 2.59 | 2.62 | 2.66 | 2.59 | 2.62 | 2.66 | |||||||||||||||

| Cooling Capacity Min./Max.(4) | kW | 1.99 | / | 4.32 | 2.85 | / | 6.20 | 3.97 | / | 8.64 | 4.80 | / | 10.44 | 2.85 | / | 6.20 | 3.97 | / | 8.64 | 4.80 | / | 10.44 | |

| Cooling Power Input Min./Max.(4) | W | 545 | / | 1720 | 760 | / | 2399 | 1090 | / | 3440 | 1245 | / | 3929 | 760 | / | 2399 | 1090 | / | 3440 | 1245 | / | 3929 | |

| E.E.R Min./Max.(4) | W/W | 2.51 | / | 3.65 | 2.58 | / | 3.75 | 2.51 | / | 3.65 | 2.66 | / | 3.86 | 2.58 | / | 3.75 | 2.51 | / | 3.65 | 2.66 | / | 3.86 | |

| Water Flow | m3/h | 1.04 | 1.63 | 2.06 | 2.75 | 1.63 | 2.06 | 2.75 | |||||||||||||||

| Hot Water Flow Rate | L/h | 125 | 196 | 247 | 331 | 196 | 247 | 331 | |||||||||||||||

| Rated Current | A | 6.5 | 9.9 | 12.9 | 16.3 | 4.4 | 5.7 | 7.2 | |||||||||||||||

| Max Power Input | kW | 2.0 | 3.0 | 3.9 | 4.9 | 3.0 | 3.9 | 4.9 | |||||||||||||||

| Max Current | A | 9.4 | 14.4 | 18.7 | 23.6 | 6.3 | 8.3 | 10.4 | |||||||||||||||

| Wire diameter | mm² | 2.5 | 4.0 | 4.0 | 6.0 | 2.5 | 2.5 | 2.5 | |||||||||||||||

| Fuse or Circuit breaker | A | 16A | 20A | 25A | 32A | 13A | 13A | 16A | |||||||||||||||

| Compressor | Type - Quantity/System | Twin Rotary - 1 | |||||||||||||||||||||

| Fan | Quantity | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |||||||||||||||

| Airflow | m3/h | 1500 | 2500 | 3000 | 3500 | 2500 | 3000 | 3500 | |||||||||||||||

| Rated power | W | 60 | 80 | 100 | 120 | 80 | 100 | 120 | |||||||||||||||

| Water Side Heat Exchanger | Type | Plate Heat Exchanger | |||||||||||||||||||||

| Water Pressure Drop | kPa | 14 | 18 | 20 | 21 | 18 | 20 | 21 | |||||||||||||||

| Piping Connection | Inch | G3/4" | G1" | G1" | G1" | G1" | G1" | G1" | |||||||||||||||

| Allowable Water Flow | Min./Rated./Max. | L/S | 0.18 | 0.29 | 0.48 | 0.28 | 0.45 | 0.76 | 0.36 | 0.57 | 0.96 | 0.48 | 0.76 | 1.27 | 0.28 | 0.45 | 0.76 | 0.36 | 0.57 | 0.96 | 0.48 | 0.76 | 1.27 |

| Sound pressure level(1m) | dB(A) | 40.8~50.8 | 41.6~50.1 | 41.4~51.5 | 46.9~57.1 | 38.7~49.4 | 41.2~51.4 | 42~55.4 | |||||||||||||||

| Sound power level(1m) | dB(A) | 60.1 | 61.2 | 63.2 | 64.2 | 61.4 | 63.7 | 64.2 | |||||||||||||||

| Net Dimension(L×D×H) | mm | 990*375*655 | 1110*475*810 | 1110*475*810 | 1110*475*960 | 1110*475*810 | 1110*475*810 | 1110*475*960 | |||||||||||||||

| Carton packing Dimension(L×D×H) | mm | 1165*505*960 | 1165*505*960 | 1165*505*1110 | 1165*505*960 | 1165*505*960 | 1165*505*1110 | ||||||||||||||||

| Splint packing Dimension(L×D×H) | mm | 1070*405*800 | 1210*540*960 | 1210*540*960 | 1210*540*1110 | 1210*540*960 | 1210*540*960 | 1210*540*1110 | |||||||||||||||

| Net Weight | Kg | 59 | 96 | 104 | 114 | 96 | 102 | 114 | |||||||||||||||

| Carton gross Weight | Kg | 114 | 124 | 114 | 122 | ||||||||||||||||||

| Splint gross Weight | Kg | 80 | 131 | 141 | 126 | 131 | 139 | 126 | |||||||||||||||

| Note: (1) Heating condition: water inlet/outlet temperature: 30℃/35℃, Ambient temperature: DB 7℃/WB 6℃; | |||||||||||||||||||||||

| (2) Heating condition: water inlet/outlet temperature: 40℃/45℃, Ambient temperature: DB 7℃/WB 6℃; | |||||||||||||||||||||||

| (3) Cooling condition: water inlet/outlet temperature: 23℃/18℃, Ambient temperature: DB35℃/WB24℃; | |||||||||||||||||||||||

| (4) Cooling condition: water inlet/outlet temperature: 12℃/7℃, Ambient temperature: DB35℃/WB24℃; | |||||||||||||||||||||||