Views: 1818 Author: Site Editor Publish Time: 2023-11-23 Origin: Site

Heat pumps are appropriate for reducing energy consumption while achieving increased energy efficiency in an environmentally friendly way. The increased global satisfaction with HVAC technology is a leading factor in the development of different ways to increase heat exchanger energy efficiency.

That said, the heat exchanger plays a key role in the performance stability of the entire heat pump system. All heat pump exchangers have similar basic design principles. However, high-performance heat pumps require optimum heat exchangers. Let's get started on the working principle, design, suitability and other vital aspects of a heat exchanger.

A heat exchanger is an equipment that focuses on the key parameters of the heat energy cycle. The thermodynamics allow for heat flow in fluids with varying characteristics. Heat exchanger designs range from traditional to recent innovations.

The design characteristics are determined by applications like processing plants and industries. The proven popularity of heat exchangers in HVAC systems can be attributed to their exceptional temperature distribution and cost-effectiveness. The use of heat exchangers in refrigeration systems is also highly adapted.

Thermal dynamic laws determine how heat is exchanged in the device. The natural behavior of heat is that it flows from the high temperature sections to low temperature ones. Heat pump systems basically exchange the heat from a heat source to a heat sink; they use the moving principle rather than creating heat.

The heat transfer modes are effective in ensuring the process takes place separately in the coolant. A heat exchanger, therefore, is not a single device but rather a combination of coils, plates, tubes, and other components working together to facilitate heat transfer. Let's take an in-depth look:

● Conduction - The heat transfer process involves molecules with varying kinetic energy. When his molecules collide, the ones with higher kinetic energy pass heat energy to those with a lower one. Heat exchangers have walls that act as a barrier between fluids and act as an avenue for conduction. The devices use the Fourier’s Law of Heat Conduction, and the process goes on to the point of thermal equilibrium.

● Convention - This process involves Newton’s Law of Cooling. The refrigerator of a heat pump passes thermal energy as it moves along the wall of the heat exchanger. The heated molecules expand and move upwards due to their low density. During this movement, they come into contact with the cooler ones and transfer heat energy to them. When the heated molecules lose excess heat, their density increases, and they drop down. The continuous process is known as a convection current.

● Thermal Radiation - This is the process where electromagnetic energy is emitted from a high temperature surface. The radiation is free flowing as it does not require a transfer medium.

Think of these principles as the motion course of the heat pump refrigerant. There are different flow configurations involved in the heat exchange process like:

The movement of the fluids in this heat exchanger is aligned, but the motion course is opposite. The fluids keep a constant temperature variation in the heat exchanger. They are highly efficient, hence their popularity, and the flow configuration uses a reduced surface area than the concurrent flow configuration.

These heat exchangers are suitable for gas or vapor fluids. A tube holds the liquid while the gas passes on the outer surface of the tube. The fluid motion in this flow configuration is perpendicular, and its efficiency can be rated as medium compared to the hybrid and countercurrent counterparts.

This is an innovation that blends together all the fore mentioned heat exchanger configurations. Simply put, there are several motion courses happening in the same heat exchanger. They are ideal choices for applications with constraints like pressure, temperature and cost.

All heat exchanger types have components that serve varying purposes. This category of heat pumps has plates and tubes that act as barriers, ensuring the fluids do not mix during the heat exchange process.

The material used for manufacturing the walls of the tube or plates is mostly metal. Types of indirect heat exchangers are:

● Plate Heat - these devices have thin plates closely joined together. The individual plates allow for separate fluid flow. The flow configuration of this type is countercurrent, and they allow for modifications like pillow fins or plate fins.

● Shell and Tube - this type has multiple tubes contained in a larger cylinder enclosure. The tubes are separated, where the fluids flow inside and on the outside surface of the heat exchanger tubes. Shell and tube heat exchangers allow for counter current or concurrent flow and are compatible with both single/double phase fluids.

As the name implies, the thermal energy transfer in this type does not require any separating components; rather, it uses direct contact to transfer heat. This type is a cost-effective option because of the lesser components. They are suitable for marine, waste heat systems and refrigeration.

The heat exchanger systems in heat pumps have come a long way in terms of enhanced designs, temperature distribution and cost effectiveness. The key purpose of this technology is to facilitate the thermal energy cycle in a heat pump; hence, design considerations are crucial in ensuring energy efficiency.

An example of a heat exchangers with optimum energy efficiency is the one that comes with the R290 heat pump. Some of the advancements in heat pump technology that allow for optimum efficiency designs are:

With time, technology has paved the way for materials with enhanced properties. Previous heat exchanger models offered less durability and efficiency. For instance, they were mostly produced using copper and carbon steel. These materials required thickening to make them corrosion resistant.

Today, engineers manufacture heat exchangers using materials with better thermal conductivity, while the strides in alloy composition and finishing solutions allow for long lasting and optimum performance heat exchangers.

There are various issues that are prone to occur during the operation of a heat exchanger in a heat pump. Innovations in the heat pump technology are mostly inspired by the need to tackle or eliminate these setbacks, which is why new model heat exchangers have safer designs. They come with features like spring action and floating tubes, which improve the operation safety.

This is a modern technique of manufacturing unique components for a wide range of equipment. Engineers can now enjoy design freedom as this innovation enables them to produce standard AC heat exchanger designs as well as customizations for high performance heat pumps. 3D printing also allows for smaller and lightweight components of the heat exchanger.

Heat exchanger manufacturers will be able to produce optimum heat exchangers with computerized commands. The use of AI for predicting performance issues and their solutions will spearhead parameters of the manufacturing process, making it faster and more efficient.

One solution engineers are considering to use for maximized efficiency is the introduction of nanomaterial in the heat exchanger design. This is projected to enhance the heat exchange process and reduce the components required to manufacture this device.

This advancement will allow for more compact designs which can be incorporated in high performance heat pumps. They will have less weight and improved heat transfer.

Heat exchangers are devices calibrated to facilitate the passing of heat between fluid molecules with different temperatures. There is a wide range of fluid types that are compatible with air conditioner heat exchangers that fall under the process fluid or utility fluid categories.

The fluid that is commonly used in modern heat pumps is a refrigerant. These devices play a crucial role in various industries for both heating and cooling processes.

Basically, these systems utilize space for thermal energy transfer. The heat exchanger in HVAC systems operates through exchanging heat and cold air. Some heat exchanger problems are likely to affect the overall function of the entire HVAC system.

A damaged heat exchanger cannot facilitate the heat exchange process, which affects the comfort and air quality inside the building.

There exist different types of heat exchangers planned for certain fluids. For instance, in a water-to-air type of heat exchanger, there are S-shaped metal tubes and coils. It generates heat by exchanging thermal energy between the vapor gasses and the surrounding air. Its appearance varies based on its purpose and context.

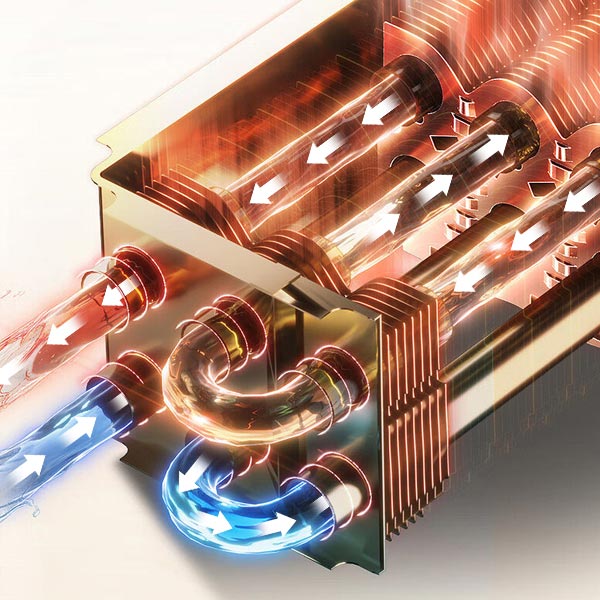

Fig 1: Illustration of a Heat Exchanger

Heat exchanger technology can be applied in various systems and devices. The HVAC System

Makes us of heat exchangers for a need of room temperature regulation by transferring heat between air and other.

fluids. HVAC uses a scroll compressor heat pump to compress air in a circular motion, which increases efficiency in change of temperature.

There are various types of heat pumps with different heat exchange properties supplied by SPRSUN. Some of them include Split Systems, Cold Climate systems, and DC Inverter systems.

Chemical plants and manufacturers use heat exchanger technology to control temperature during different processes. The automotive industry also uses these devices to cool vehicle engines.

The most common technique used to diagnose leaking cracks in air conditioners is by measuring the ambient carbon monoxide. The measuring process involves measuring ambient CO in the conditioned space while the heat is running using a CO detection device.

Any measurement greater than zero indicates that there are leaking cracks in the air conditioner. Flame displacement observation can also be carried out to test cracks in air conditioners.

The flame should remain stable during the test without any movement. However, when the blower makes the flame move, it is certain there are cracks leaking fluids outside the heat exchange. Combustion analysis can be used to reveal cracks in air conditioners.

An analysis can show the amount of CO and determine if any leakages have occurred. Additionally, you can have a professional carry out a visual inspection to detect cracks.

The first step to take after noticing cracks on a heat exchanger is to exercise high safety standards. A professional should be sought to deal with the leaking air conditioner since handling carbon monoxide can be fatal.

In most cases, a cracked heat exchanger cannot be repaired. Therefore, replacement is the recommended solution to a cracked air conditioner. However, the cost of replacement can be costly, especially when replacing the whole furnace.

In addition, there are preventive measures that can solve the maintenance part of heat exchangers. The practices include regular cross-examination of air conditioners by professionals, replacement of air filters, and giving good space to air conditioners. Gadgets that can detect carbon monoxide can be fixed in air conditioners to detect leakages.

The surroundings of your heat exchanger are a key factor in determining how often you perform the maintenance routines. Most of these devices are located at the base near the central air system. A professional can access the air exchanger to examine any faults and replace any cracks.

The whole system can be regularly cleaned, including ducts and air filters. Regular replacement of air filters is highly encouraged to prevent dust from building up, causing overheating and other defects. How long do heat pumps last? The answer to this question is directly linked to the operation of the efficiency and durability of its components, like a heat exchanger.

A constant air flow rate between outgoing and ingoing air is also recommended to create a balance in the entire system, thus increasing longevity. Periodic inspection should also be carried out to detect the emission of carbon monoxide.

1. Fluid Properties determine the type of heat exchanger to use. Properties such as

viscosity, acidity, flow rate, and thermal qualities matter a lot when selecting a heat

exchanger. For instance, you should avoid using plate heat exchangers with fluids of high-flow

2. The different types of heat exchangers come at varying cost; intricate models are more expensive. Nevertheless, all heat exchanger types are relatively affordable and low maintenance.

3. Materials used to produce these devices are a crucial consideration when looking for the ideal model. Materials that are efficient in thermal conductivity are good raw

materials for a perfect heat exchanger. Moreover, the availability of these materials plays a

key role in choosing a heat exchanger.

4. Function and Pressure Limits determine the heat exchanger’s mode of operation, such

as condensing and boiling. Some heat exchangers can sustain higher pressure than others,

Thus, it is important to select optimum heat exchanger designs for complex heat pumps.

Based on the information provided, it is evident that heat exchangers are essential for the overall performance of all heat pump models. These devices only get better with time; older heat exchanger models exhibited a higher rate of performance issues, but the recent models allow better heat transfer, are more sustainable, and cost effective.

The innovations in the heat exchanger technology mark an even better future, projecting optimum performance, compact, cost-effective, and lightweight heat exchangers.

As we expect more innovations, these devices continue to perform their critical role in the heat pump industry. These innovations are geared towards optimum energy efficiency and sustainability. For top-quality and energy-efficient heat exchangers, contact or email SPRSUN for a prompt quote.

2021-12-06

2022-01-07

2021-10-30

2021-11-30